# Enhancing Your DIY Solar-Powered Window Air Conditioner

Written on

Chapter 1: Introduction to Power Management

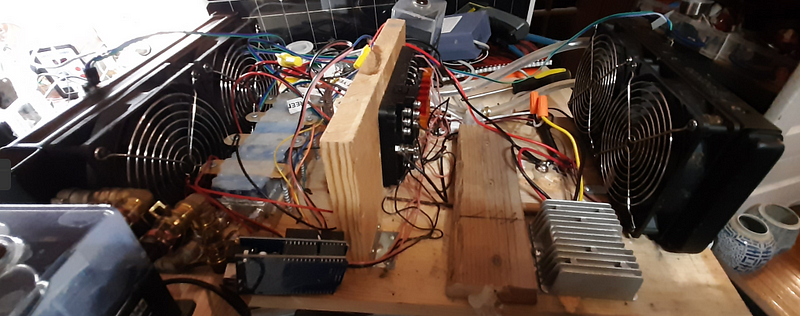

In this segment, we will explore various enhancements to the Solar Peltier System. Throughout this project, I have gained valuable insights into managing power consumption, understanding how power supplies produce heat, and recognizing how lower voltage amperage can lead to significant heat generation. I have removed the unit from its window setup to implement upgrades aimed at improving cooling efficiency. By reducing the heat generated by the power supply and wiring, we can allocate more energy to the Peltier modules, thereby enhancing the room's cooling capabilities. It has become clear why many online Peltier projects underperform; they often generate more heat than they dissipate. The original 12V system was producing excessive heat in the wiring, so it’s time to increase the voltage and minimize the amperage flowing through the wires!

Transitioning to 48V @ 6A is a much better solution compared to the previous 12V @ 24A setup. Previously, the wires were reaching dangerously high temperatures of 140°F (60°C) or more, and I have no intention of risking a fire hazard.

Section 1.1: List of Upgrades

Here’s a straightforward list of the upgrades I’ve made:

- 48V 400W Power Supply: This should operate cooler because it will run below its maximum capacity. The previous supply was frequently pushed to its limits, likely contributing to excess heat.

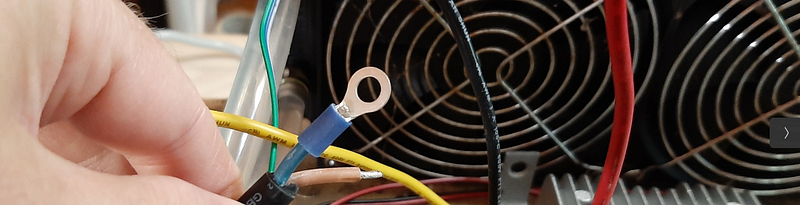

- Soldered and Screw-Down Connections: Stricter connections help minimize waste heat.

- Peltier Modules in Series: These are now directly connected to the 48V supply, while other 12V systems receive power from a separate 48V to 12V converter.

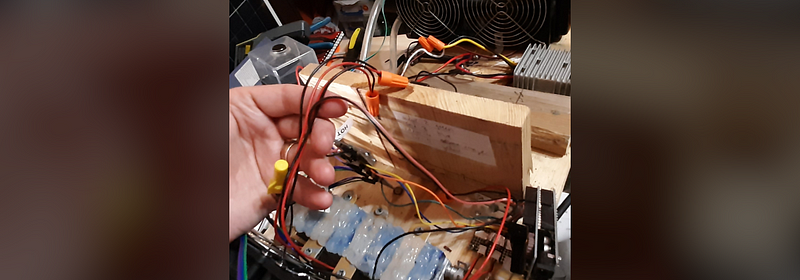

- Inline Fuse for Peltiers: Following the smoke test, I recognized the necessity of a fuse for the 48V @ 6A Peltier modules. I had a 15A fuse on hand, which should offer protection against potential malfunctions.

- Wire Nut Connections for Temporary Links: These ensure tight connections while minimizing waste heat.

- External Power Supplies: As with the previous setup, I’m placing all power supplies outside. Eventually, I plan to relocate the fan below the power supplies to reduce the heat load.

Section 1.2: Connection Enhancements

I located some terminal connectors and soldered the output wires. Other connections are securely fastened with screws and washers for reliability.

To ensure solid connections, I used wire nuts for temporary setups, with the intention of soldering these joints once I’m satisfied with the performance.

The 48V to 12V converter, designed for use in golf carts, powers the 12V components efficiently. These converters can handle up to 240 watts, and by isolating the 3–6W pumps and fans, they barely warm up even after extended use. I will also position this outside.

I have four 12V Peltier units in series, which perfectly match the 48V configuration. This setup allows me to utilize my lawn mower and e-bike batteries as power sources. I simply connected them in series, and if successful, I plan to shorten and solder the wires to reduce resistance.

An inline fuse was added after the smoke test, as I realized that the system needed protection against short circuits. These compact fuses can be easily integrated anywhere in the circuit.

Chapter 2: Smoke Testing and Performance Evaluation

Following a half-hour of operation, I recorded the following temperatures and power usage, starting with a room temperature of 77°F (25°C):

After 30 minutes: - 48V Power Supply: 110°F (43°C) - 48V to 12V Converter: 85°F (negligible) - Hot Side: 96.5°F (35.8°C) - Cold Side: 62.5°F (16.9°C) - Power Consumption: 260W

For Comparison: - Previous Power Supply: 139°F (59.4°C) - Previous Power Consumption: 200W

This new setup uses an additional 60W of power while generating significantly less waste heat—indicating a remarkable 34°F (~18°C) temperature differential compared to the previous 12V system. This difference is nearly six times the 5°F (3°C) variance I observed previously. It will be interesting to see if this trend continues when the unit is installed in the window. The benchmark temperature during the test was 77°F (25°C); however, it may not perform as dramatically with higher outside temperatures of 85°F (29.4°C) or 90°F (32.2°C), as it will have a smaller temperature gradient to work with. Still, the extra 60W of power should contribute significantly to overall cooling.

A mere 10°F (6°C) difference would greatly enhance the room's comfort level.

Section 2.1: Future Plans

Next, I intend to implement a swamp cooler utilizing a peristaltic pump and ultrasonic misting technology, regulated by an Arduino. If successful, this system could condense water in the room and utilize it for evaporative cooling outside, potentially adding 250-500W of cooling power per liter of evaporated water. This addition should significantly boost the overall efficiency of the air conditioning system.

Section 2.2: Project Updates

I have updated my GitHub repository with the latest operational data and charts. Unfortunately, I only logged a couple of hours of data until 11 AM, and encountered some sensor issues due to moisture exposure. Despite these setbacks, the room temperature still reached 80°F, indicating that the A/C unit is not yet effective enough to keep the temperature down. I will need to further explore the ultrasonic misting system and possibly incorporate phase change materials to enhance performance.

I receive affiliate commissions for links in this article, which helps support my projects.